[Frivolous Note: The “juice worth the squeeze” line is one of my favorite stolen phrases. I want to give credit to my safety colleague and friend, Sue Abernethy, but I also have heard it belted out in a Lizzo song, so the source remains unclear officially. It also appears to have been said by Tim Olyphant in a 2004 movie. There is no question, however, that I stole it from someone far wittier than me.]

It’s safe to say that I am Old School when it comes to safety training. I’ve been facilitating safety training in person — in a classroom, beside a process tank, in a laboratory, outside a construction or remediation project job trailer, next to a forklift or in a maintenance shop — for a few decades now.

Teaching is one of the most rewarding aspects of my work life. My first experience with safety training was as an employee, attending a 40-Hour Hazwoper course (delivered under the OSHA emergency temporary standard in a year I will not divulge.) It was provided by someone clearly not into the gig. It was disorganized. It was boring. He read from the slides and the regulations themselves and at the end of it, having barely survived chemistry at Cornell, I was fairly certain I would perish because I could not recall the difference between an oxidizer and a pyrophoric. I felt the opposite of safe; I felt entirely unprepared for my job in the field.

Likewise, my forklift operator training. Lackluster, not the least bit practical, all about the physics of forklifts and the regulations, without a clue how to operate one safely. When the classroom session was complete, I was put on the forklift in a warehouse and told to “get some practice.” I ended up seeking out one of the more experienced guys I worked with to coach me when he had a minute or two of downtime. Thankfully, he was patient and a good teacher.

Similarly the confined space entry course I took. Granted, confined spaces are a complex topic. It was like someone took an entire 1000-piece jigsaw puzzle box and dumped out the pieces, leaving me to sort it out myself as the instructor stumbled along, oblivious to the fact that everyone was overwhelmed and entirely checked out.

When I got called upon to lead some safety meetings, this about four nanoseconds after my boss realized I was comfortable speaking in front of a group — thank you 4-H Public Presentations!– I vowed I would do things differently.

It would be interactive, I would simplify things as best I could, we would talk about scenarios, we would make sure everyone left with an understanding of what they needed to do their job. I would watch for the guy (because back then they were almost exclusively men) who looked baffled, because even if he wasn’t a particularly stellar student he had the right to be safe on the job. [My mom was a teacher, so I think the desire was inherited. Thanks, Mom.]

I started out lousy, but it got better over the years, and I found that having to teach safety meant I really had to understand the concepts and be able to parse them out for the learner. It almost became a game to simplify difficult concepts, to take that confined space jigsaw puzzle, and teach employees how to sort the pieces, create the frame by matching up the shapes and the artwork, and see it all come together.

Fast forward twenty-five years to 2016. Safety eLearning was becoming a thing. I checked it out. I was less than impressed. For all of the same reasons that my first safety training experiences as a learner were a bust.

It was uninspired, it wasn’t interactive, it was typically irrelevant to the employee’s needs on the job, and no one checked in to see if the learner actually understood what was important.

Rather than walk away from the problem, I considered the facts.

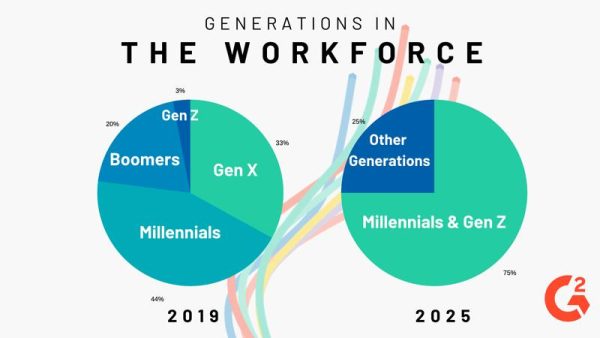

- Safety eLearning was not going away. The youngest of the employees in the workforce embrace and even expect eLearning to be a part of their job. Of course, that’s even more true in the future — check this out:

Source: Executive Growth Alliance

Even a dinosaur like me could see the writing on the wall.

I could either be a part of the problem, or a part of the solution. So I did what any dyed-in-the-wool, Old School, look-’em-in-the-eye safety trainer would do.

I started a safety eLearning business.

We started to create content that solved the problems I saw with what was currently on the market. I knew this was going to be a challenge for safety professionals like me, and I wanted to be there to provide my colleagues with a solution.

Now, dear readers, lest you think I have drunk the Kool Aid and am now a rabid safety eLearning fan who thinks it is a be-all, end-all training solution, that’s simply not the case.

I am still a staunch believer that certain content is best delivered face-to-face with the learners, where a confused look on the part of a participant can be read and the delivery modified, or a question asked and a tangent pursued until a complex issue has been resolved.

Here’s a little more data:

- On average, it takes approximately 200 hours to build one hour of eLearning with audio from the ground up, from concept to completion, with the product an interactive course customized for the client’s workplace and hazards.

That course-build requires a whole village — a SME (subject matter expert), a team to create a high level design of the content, an instructional designer, someone to gather appropriate images and create interactions and quiz questions, and a voice over artist. A team to test its functionality and fit for the learners. Trust me, our team has tried to break this 200-hour rule of thumb, but as efficient as we are, the rule holds true. (If you opt to build the course in another language, say Spanish, then you add translation and an additional voice over artist to the mix.)

(If you want to record into your phone over your own PowerPoint slides, that is cheap and easy, but see above about “uninspired.”)

Sounds time-consuming, right?

Another data point:

- Once the course is built in the appropriate software, it takes approximately one year to 18 months for an organization to select, set up and implement a LMS (or learning management system) to house and administer the courses they have created. (Source: The Learning Guild, Learning Management Systems 2022) This data, sadly, also true, based on our own one-rat study. It took us two years to select and then customize the right LMS, but we’ll defend ourselves by saying that we were building it for five or six unique clients’ needs in mind. The LMS software does all the magic of providing access to the content, recording the learner’s responses to interactions, and tracking every bit of their interface with the course.

Sound like a time investment you’re not sure is worth making?

Folks, I agree.

Which leads us back to the original question —

When is the juice worth the squeeze?

- When you have a significant-sized and fairly uniform audience that needs to be informed about hazards and policies and information.

- Examples include:

- Project Contractor Safety Orientation

- Basic Electrical Safety

- Lockout/Tagout for Affected Employees

- New Employee Onboarding

- Temporary Employee Safety Orientation

- Safety Meetings or Procedure Reminders that are frequently accessed, such as “Headquarters Building Emergency and Evacuation Procedures” or “Factory PPE Requirements.”

- Examples include:

- When that audience is often one-and-done or has a high turnover, making in-person training sessions expensive based on the frequency of sessions.

- Examples include:

- Construction project contractors

- Temporary/conditional/internship employees

- Employees required to be provided with awareness level training

- New employees in a high-turnover position/industry

- Examples include:

- When the risk and liability and compliance bar is high for the employer or organization. For example, if there’s a significant burden of regulatory information to be conveyed, policies or other information which must be shared and/or demonstrating an understanding of the content is significant to the organization. In these situations, the LMS itself does the documentation and recordkeeping in such a way that “he said, she said” disputes evaporate.

- Examples include:

- Project contractor orientations for construction projects

- Initial new employee orientation for high-turnover workplaces/positions

- Temporary employee orientations.

- Examples include:

Most of my safety colleagues in private industry are burdened by the time such training takes away from their other duties, and how difficult (or impossible) it is to do so with consistent messaging, quality and ironclad documentation.

We created a little eLearning module about that challenge:

Lisa and Matthew’s Coffee Klatch / eLearning 101

You’ll see that construction project contractors hit all three criteria: Large audience, one-and-done, and high risk. I’ll speak more to that specific audience in an upcoming blog.

So consider wisely if and how your organization could and should use eLearning when it comes to safety topics.

Take it from this old-timer.

Make sure the juice is worth the squeeze!